In this post we will be looking at the Cold Metal Fusion (CMF) AM method, and we will be answering that exact question. What is it?

Cold Metal Fusion is a powder-based indirect metal printing process developed by Germany-based company Headmade Materials. This company was recently in the news because they completed a €1.9 million funding round.

The technology promises to allow those with polymer laser sintering machines to move over to the metal-side. Just to be clear, they are developing materials, and not printers (at least not yet).

But wait… how can it be “sinter-based” and “cold” at the same time? You need heat for sintering, right? Yes.

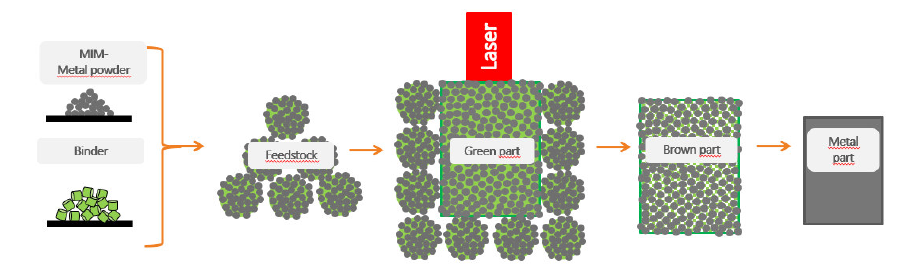

Looking at the process diagram below, the Headmade Materials feedstock is metal on the inside and is coated with a polymer binder.

The part begins as a CAD file, and goes through a slicer to slice the model into layers to be printed in the sintering machine. You can see one layer in the image below.

The printing occurs under 80 degrees Celcius, which is achieved with the power range of low powered plastic sintering systems. So that is why it is named “cold”.

As with a normal SLS system, the wiper deposits a fresh layer of unsintered powder over the previous built layer, the laser sinters it, and it all repeats until the part is complete.

Because the metal particles are not exposed to any air (being protected in a polymer) there is no oxidation of the metal. Additionally, due to the “cold” process, there is no heat impact on the unused powders, so it is apparently very easy to simply reuse old surplus powder.

And being an SLS based, it requires zero support structure too (according to the website), which is nice. All in all, it seems like a fairly efficient process.

But wait… the process is not complete.

Post Processing

After the “green” part is removed from the printer, it is de-powdered and sent for any post-processing such as milling or drilling, as the green part with binder is still strong enough to work on.

After the post-processing, the green part is sent for debinding, in which the sintered (and soluble) plastic is dissolved from the metal structure, leaving the so-called “brown part” ready for the final step: actual metal sintering.

And for this step you need a furnace capable of reaching metal sintering temperatures.

The metals on offer by the company at the moment are stainless steel 316L, cobalt-chrome, titanium Ti6Al4V and tungsten. Several others are under development, including copper, tool steel, and an unnamed superalloy.

The furnace heats the brown parts, and burns any remaining binder from the part. Eventually, the remaining metal particles are sintered and the full metal part emerges from the furnace, as you can see below.

The company website claims that this system is the “lowest investment cost of all metal 3D printing processes for series production”, and by “series” they claim that the system is good for production runs of up to 100,000 parts.

What happens after 100,000 parts is not mentioned on the site, but it’s more likely to be a question of economics. Customers may wish to switch to another manufacturing method with numbers above that.

But still, producing 100k units of something and being more economical than MIM/high pressure casting at that level is not bad going, economically speaking.

We will watch their development with interest, while asking ourselves if anything that requires metal sintering temperatures as the primary mechanism for metal fusion can truly be referred to as a “cold” process.

亞洲大學3D列印研究中心

亞洲大學3D列印研究中心