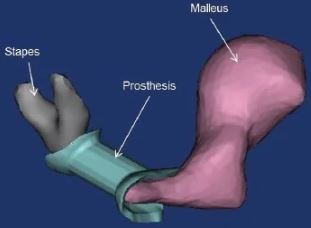

While printing finds itself in wide use among the medical prosthesis community, there are certain organs that are fairly elusive. Although 3D printing offers precise control over minute details, there are always worries about part quality and precision. Parts like the ear, particularly for sufferers of hearing loss, can be intricate pieces to produce as it is. Now, Maryland researchers Dr. David J. Eisenman and Dr. Jeffrey Hirsch have demonstrated that a standard, commercially available 3D printer can produce an effective prosthesis for the middle ear.

Ossicular chain disruption from inflammatory middle ear diseases or trauma is a common cause of conductive hearing loss. Reconstructing the middle ear standard procedure to off-set the hearing problems such a trauma creates. However, as the researchers state, no single optimal prosthesis exists as of yet. This can be due to a variety of reasons (anatomic variation, effects of the pathologic process on natural anatomy, prosthesis stability and biocompatibility).

To mitigate these factors, the researchers are turning to 3D printing and CT scans. This will allow them to properly customise the prosthesis for each patient, which is essential for parts as intricate as the inner ear. By studying the inner ears of cadavers, they hope to come up with a solution for a customisable prosthesis.

Thanks to CT scans and 3D printing a precise middle ear prosthesis may be on it’s way. While the study isn’t conclusive, it has indicated the possibility towards that direction. The researchers used three human cadaveric temporal bones with no apparent history of ear disease. They then designed a prosthesis for each bone based on the CT scans, finding that each was very unique. Next, they brought in test surgeons who they asked to insert the bone into the correct bone to see if they could determine where it belonged without prior knowledge. They were happy to find out that each surgeon was successful in this endeavour. The study concludes: “Although there are still many challenges in the commercial reproduction of this approach, this study demonstrated that production of 3D-printed middle ear ossicular prostheses is feasible. One day, we can hope that a custom-designed prosthesis will be ready for patients before they undergo an OCR. This would significantly shorten surgical time and increase the likelihood of a stable and accurate fit that will improve long-term outcomes.”

亞洲大學3D列印研究中心

亞洲大學3D列印研究中心