ON A hot February morning, Callum Harewood rolled his electrician’s van and almost died. Harewood, 37, of Warana, on the Sunshine Coast, who has no memory of the accident, was on his way to work when his van crashed on an entry road to the Sunshine Motorway at Mountain Creek.

The single-vehicle crash left him with broken vertebrae in his neck, serious bruising to his brain, nerve damage to his arms and smashed bones in his right leg, above and below his knee.

Harewood was taken to Nambour Hospital but, with 15cm of femur bone missing from his leg, was transferred to the Royal Brisbane and Women’s Hospital for a mid-thigh amputation.

As a keen surfer and tradesman, the removal of his leg would have changed Harewood’s life, but breakthrough technology saw a team of medical and design experts use a 3D printer to custom make a titanium implant that saved his limb.

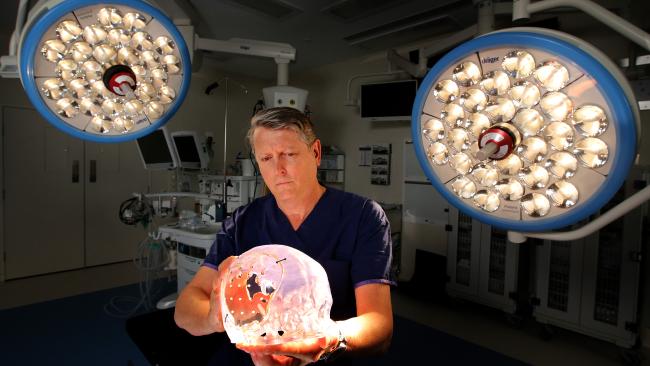

Dr Kevin Tetsworth, 59, Harewood’s orthopedic surgeon at the RBWH, says Harewood was one of six patients who received custom-designed 3D-printed implants at the hospital in the past year.

“Callum had a terrible injury,” Tetsworth says. “There was so little bone left … some of it was lost on the street and there would have been dead and really dirty fragments of bone. The result was a 15cm missing section and nothing to put screws into. Part of his cartilage was missing too.”

Scans of Harewood’s injury were sent to an American company called 4WEB Medical in Texas, and after collaboration between a design engineer, medical modeller, surgeon and orthopedic engineer, a custom-made titanium implant was created.

“We designed a special implant, which replaced some of the missing cartilage and supported a bone graft,” Tetsworth says.

“Without a custom-made implant, it would have been impossible. Nothing off the shelf would have worked and he would have had a mid-femur amputation.”

But Tetsworth says the technology is just the “tip of the iceberg” as medical 3D printing moves towards bio-compatible implants that allow the patient’s own tissue or bone to regenerate before the 3D scaffold dissolves away.

“I’ve been a surgeon for 30 years,’’ Tetworth says. “This is a very exciting time to be in medicine.

“I’m very jealous of doctors entering medicine now … they will be able to do things I can only dream of.’’

Queensland University of Technology scientist, Associate Professor Mia Woodruff, is at the forefront of 3D printing technology and its role in transforming the face of medicine. As head of the university’s Biofabrication and Tissue Morphology Group, Woodruff, 34, has dedicated her career to developing custom-made 3D-printed body parts – bones, cartilage and tissue – with applications for birth defects, cancer, and trauma sufferers. She has been a key agitator in the creation of the Australian-first Herston Biofabrication Institute, announced by the State Government this week as “the hospital of the future”.

A partnership between QUT and Metro North Hospital and Health Service, the institute will be based over two floors of Block 7 at the RBWH. It will open next year and develop technology for personalised medicine and biocompatible 3D-printed body parts, which is a key focus of future medical research. Funding will come from a mix of state, federal, philanthropic and industry partners, and will bring together up to 60 researchers, scientists and clinicians to develop 3D scanning, modelling and printing of bone, cartilage and other human tissue.

Metro North Hospital and Health Service expects investment in the institute in the next five years to be between $10-$15 million per annum and that it will position Queensland as a “global leader” in advanced manufacturing and medical 3D printing. “This is revolutionising every industry in the world,” Woodruff says. “And biofabrication and 3D printing personalised implants are the future of medicine. We’re using 3D printing technology to create patient-specific, anatomically precise implants for patients with large amounts of tissue loss.

亞洲大學3D列印研究中心

亞洲大學3D列印研究中心